Sudsy Space: Second Home Holland Park by selgascano

Foto: selgascano

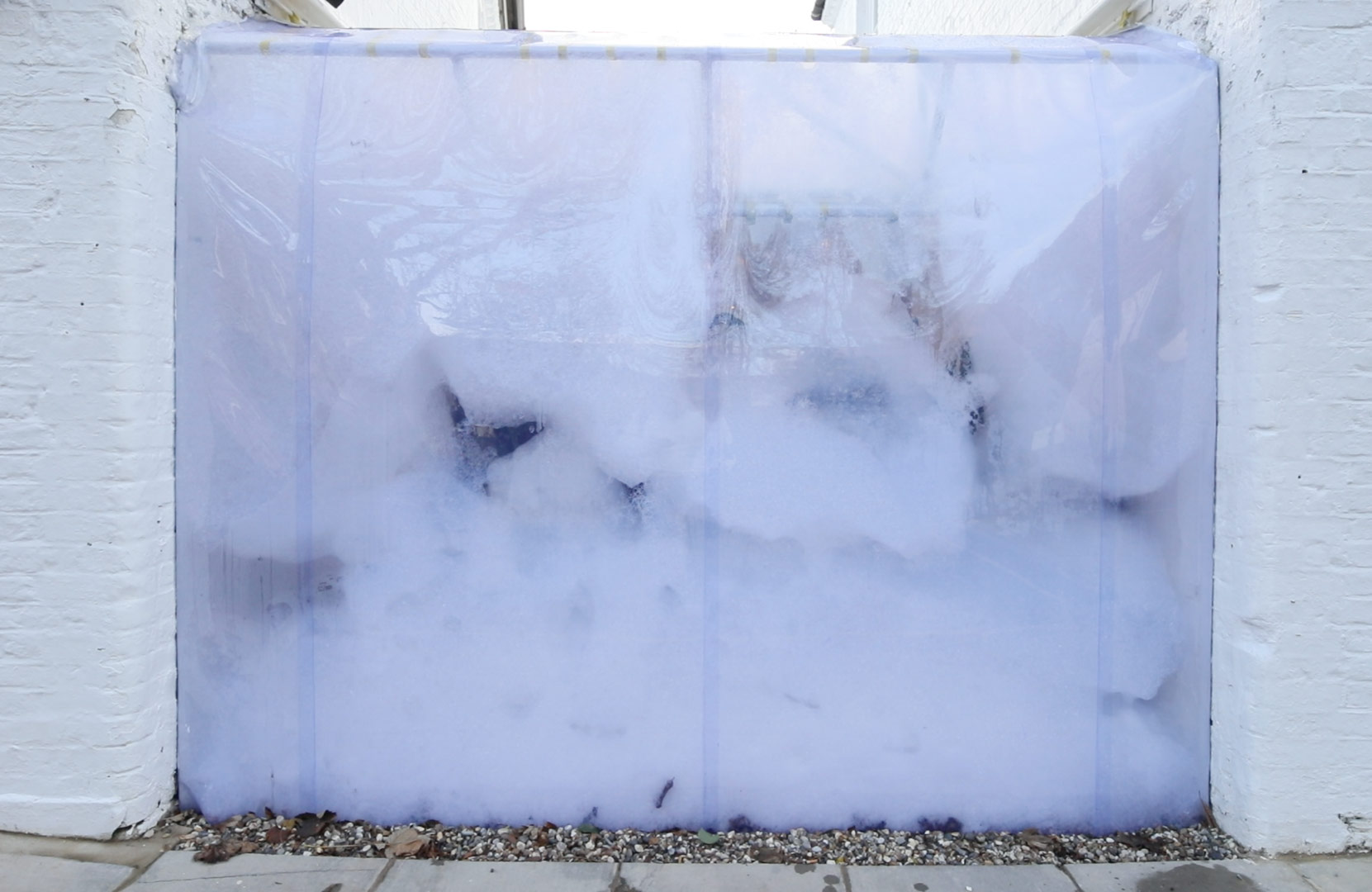

From the street, visitors enter the seemingly modest building complex of whitewashed brick and find themselves in the foyer of the narrow, two-storey passageway building which connects two former warehouses. From here, they reach the inner courtyard, which was once open to the sky but has now been topped with a translucent synthetic roof and transformed into a cafeteria. The roof consists of two layers: A sheet of EFTE plastic has been placed over a layer of PVC glass. The result is elastic and chemically resistant.

The first step in building the courtyard roofing was the installation of steel supports at the edge of the yard. Along the existing brick walls, two horizontal steel angles were attached. Where there is no wall, the architects have added trussed girders in order to complete the framing of the courtyard. After this, the ETFE sheeting was stretched between the steel supports to form the topmost layer of the synthetic roof, then the lower layer was stretched out as well, using polypropylene straps to fix it to the supports. Finally, the steel profiles were sealed on their upper, exterior sides.

The highlight: as needed, soap suds can be blown into the interstitial space with a foam machine. It takes about 20 minutes to completely fill the two-layer roof with sudsy bubbles. An added benefit is that the suds also work as insulation and soundproofing. The effect lasts about a day.

For a video and pictures of the installation process, go to:

The first step in building the courtyard roofing was the installation of steel supports at the edge of the yard. Along the existing brick walls, two horizontal steel angles were attached. Where there is no wall, the architects have added trussed girders in order to complete the framing of the courtyard. After this, the ETFE sheeting was stretched between the steel supports to form the topmost layer of the synthetic roof, then the lower layer was stretched out as well, using polypropylene straps to fix it to the supports. Finally, the steel profiles were sealed on their upper, exterior sides.

The highlight: as needed, soap suds can be blown into the interstitial space with a foam machine. It takes about 20 minutes to completely fill the two-layer roof with sudsy bubbles. An added benefit is that the suds also work as insulation and soundproofing. The effect lasts about a day.

For a video and pictures of the installation process, go to: