Automated production

Robot-Assembled Wooden House by Auar

© Naaro

Engineered houses are currently experiencing a boom. Many are modular and produced with a great degree of prefabrication, but few are automated to this extent or made locally. At Auar (Automated Architecture Ltd – pronounced like “our” – industrial robots do the assembly work. A flexible, modular wood-building system such as this should keep construction and costs under control.

© Naaro

The idea

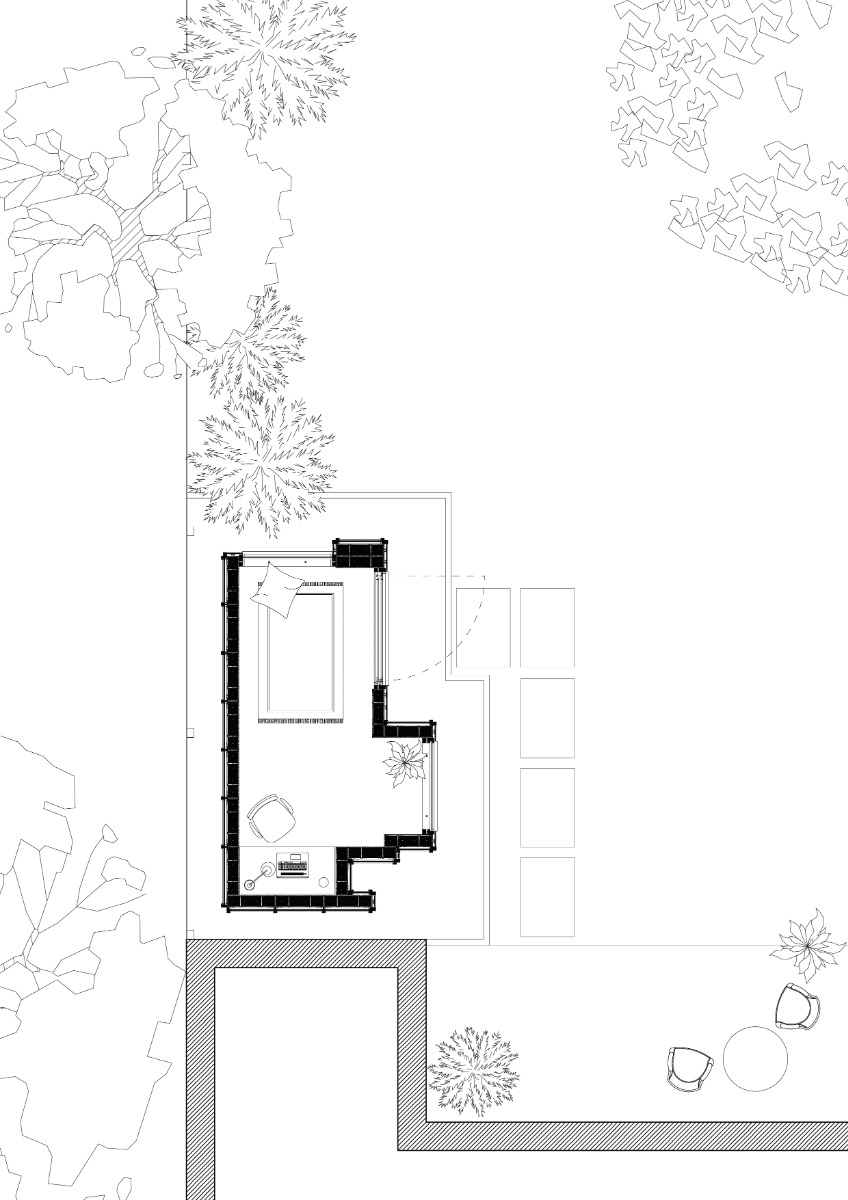

Music is not only in the air, but in construction as well: this practice room for a cellist measures just 10 m² and was built by industrial robots according to a universal system that can join double-walled wooden modules in endless variations. At first, there were several potential solutions for this prototype, each of which offered a different treatment of the southeast-facing lot. Some opened onto the garden; others were more withdrawn; a few integrated a skylight, and others featured an alcove. The final variation (with the skylight) was ultimately created with the user: it is a black-framed, long block from which a bay window appears to emerge in two steps.

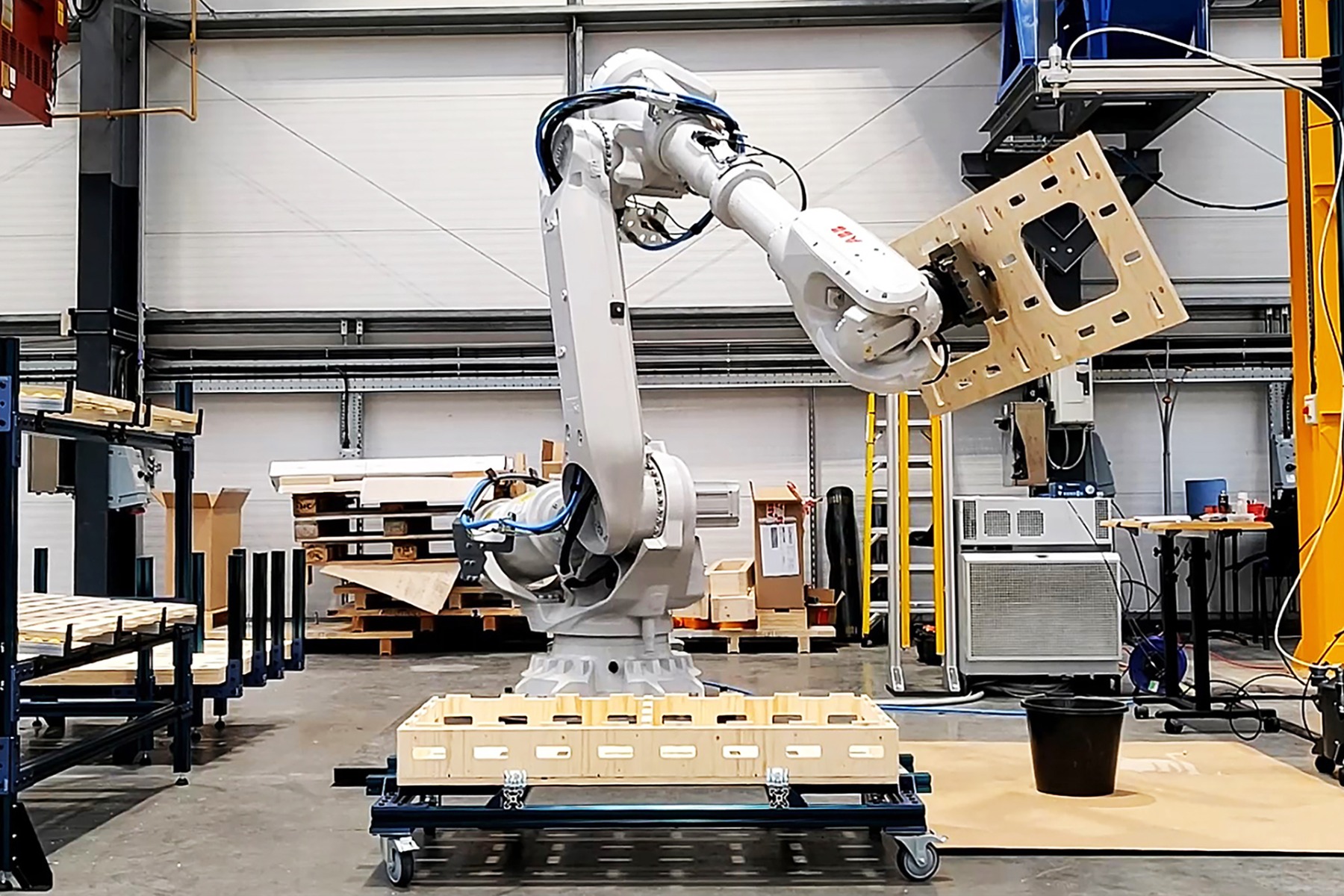

The assembly

The modular wood-building system by Auar, a design and technology company with offices in Bristol and London, promises climate-friendly construction, as it is decentralized and remains close to the wishes (and the future home) of the resident. First, an industrial robot turns wooden plates into modules that are easy to transport. Subsequently, tradespeople assemble the modules on site. Local production and the material used – wood – underscore Auar’s sustainable approach.

© Auar

The prefabrication

The cost advantages of the modular wood-building system depend not only on progress in robotics and automation, but also on the quality of the chosen construction method, which promises infinite variations for the same prices. The great degree of prefabrication, short production chains and local manufacturing also add to the appeal of the project.

© Naaro

© Naaro

The prospects

The modules are produced where the building will ultimately stand. “Starting with small or difficult to develop sites,” says Auar, “including backyards / infill sites. These include interim uses and temporary structures. The approach is participative: “We take a micro-factory approach for localized production that enables community participation in designing and building the homes they need, creating local jobs.”

© Naaro

The website makes building a house seem like ordering something from a catalogue: “You tell us about your site, budget and design requirements. We work with you to produce a design using our platform and building blocks. When you are ready, we deliver the required components and assemble the dwelling.”

Architecture: Auar (Automated Architecture Ltd)