New natural insulating material made of lignin-based aerogels

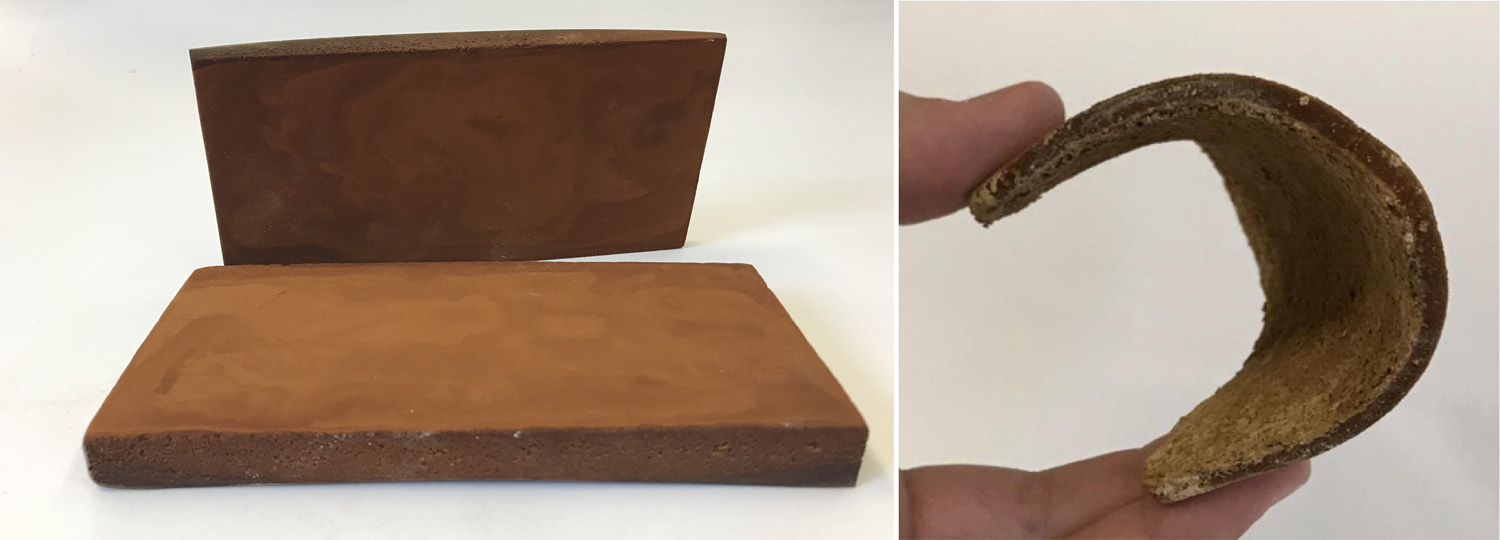

Links: Resorcin-Lignin-Formaldehyd-Aerogelplatte; Rechts: Lignin-Aerogele können auch in flexibel Formen produziert werden (Foto: Joana Gil, TUHH)

First, a number of term definitions are required in order to be able to classify the new biological material "lignin-based aerogels": The term lignin comes from the Latin word 'lignum' for wood, and describes the solid biopolymers that are stored in the cell walls of plants and which are responsible for lignification. Aerogels are solid, highly porous, nanostructured materials with low density and low thermal conductivity. The main objective of the project "The material use of lignin: nanoporous materials" was to expand the scope of application for products containing lignin. This initially required a fundamental understanding of the property functions of lignin production and of further processing. The material properties are specifically controlled by the lignin extraction itself and the type of subsequent chemical cross-linking.

The production of pure lignin aerogels is not yet possible. However, a team led by Irina Smirnova, professor at the Institute of Thermal Process Engineering at the TU HH, has made some progress towards this goal. "Conventional lignin is usually sulphurous or contaminated with other artefacts, therefore the use of lignin as a base or additive for many new applications is limited or impossible", is how the challenge of lignin production is described in the project report. The scientists used the lignin from residual beech wood and wheat straw, which was obtained in the consortium using two environmentally-friendly processes, the so-called Organosolv and Aquasolv processes. In the Organosolv process, lignin is separated using organic solvents. The Aquasolv process is based on high-pressure hot-water hydrolysis.

Through different gelling strategies, the lignins were subsequently cross-linked, gelled and dried and thus converted into aerogels. One of the most successful approaches led to hybrid lignin-polyurethane aerogels with an adjustable density between 50 and 250kg/m3. The lignin content is 78 percent and the process has been increased to pilot-plant scale. In order to produce an insulating material from the aerogel type, the aerogel is merely dried and can be used as an insulating material without further processing. The insulation panels developed from it achieve a thermal conductivity of 24mW/m·K and thus clearly exceed the insulating properties of polystyrene and rock wool. Also promising are lignin-based resorcinol-formaldehyde aerogels with a very broad spectrum of adjustable properties, which are up to 70 percent lignin-based.

Two spin-offs of the research group at TU HH will be dedicated to further research and the market introduction of lignin-based aerogels: BioMP bundles skills in the field of hot-water hydrolysis and the production of lignin for sampling and further processing. Aerogelex manufactures various types of organic aerogels and offers among other things lignin-PU aerogel panels for industrial tests.

The production of pure lignin aerogels is not yet possible. However, a team led by Irina Smirnova, professor at the Institute of Thermal Process Engineering at the TU HH, has made some progress towards this goal. "Conventional lignin is usually sulphurous or contaminated with other artefacts, therefore the use of lignin as a base or additive for many new applications is limited or impossible", is how the challenge of lignin production is described in the project report. The scientists used the lignin from residual beech wood and wheat straw, which was obtained in the consortium using two environmentally-friendly processes, the so-called Organosolv and Aquasolv processes. In the Organosolv process, lignin is separated using organic solvents. The Aquasolv process is based on high-pressure hot-water hydrolysis.

Through different gelling strategies, the lignins were subsequently cross-linked, gelled and dried and thus converted into aerogels. One of the most successful approaches led to hybrid lignin-polyurethane aerogels with an adjustable density between 50 and 250kg/m3. The lignin content is 78 percent and the process has been increased to pilot-plant scale. In order to produce an insulating material from the aerogel type, the aerogel is merely dried and can be used as an insulating material without further processing. The insulation panels developed from it achieve a thermal conductivity of 24mW/m·K and thus clearly exceed the insulating properties of polystyrene and rock wool. Also promising are lignin-based resorcinol-formaldehyde aerogels with a very broad spectrum of adjustable properties, which are up to 70 percent lignin-based.

Two spin-offs of the research group at TU HH will be dedicated to further research and the market introduction of lignin-based aerogels: BioMP bundles skills in the field of hot-water hydrolysis and the production of lignin for sampling and further processing. Aerogelex manufactures various types of organic aerogels and offers among other things lignin-PU aerogel panels for industrial tests.