Robotic production

An Innovative Facade Garment for Textile Research

New building for textile research at Reutlingen University, © Frank Kaltenbach

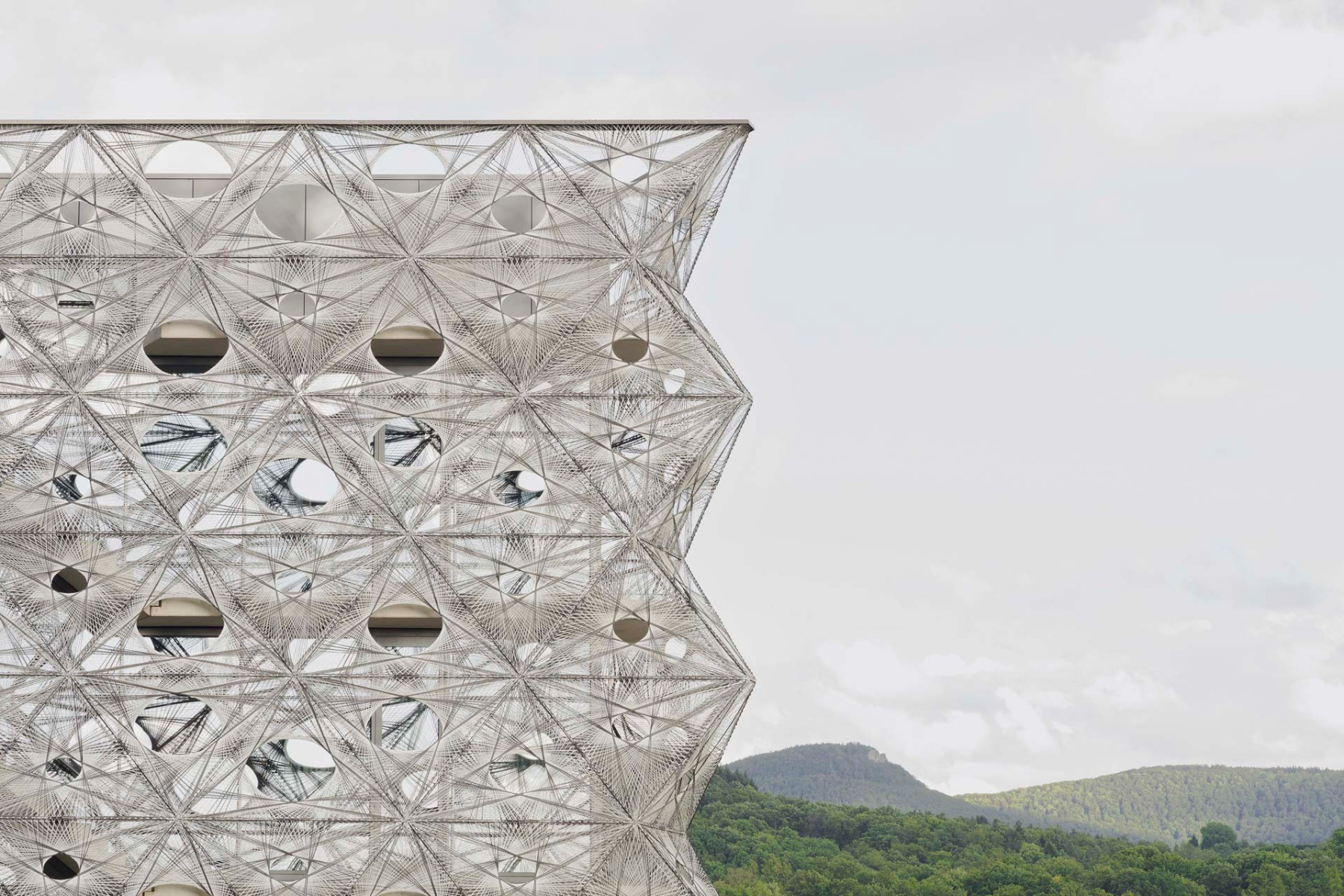

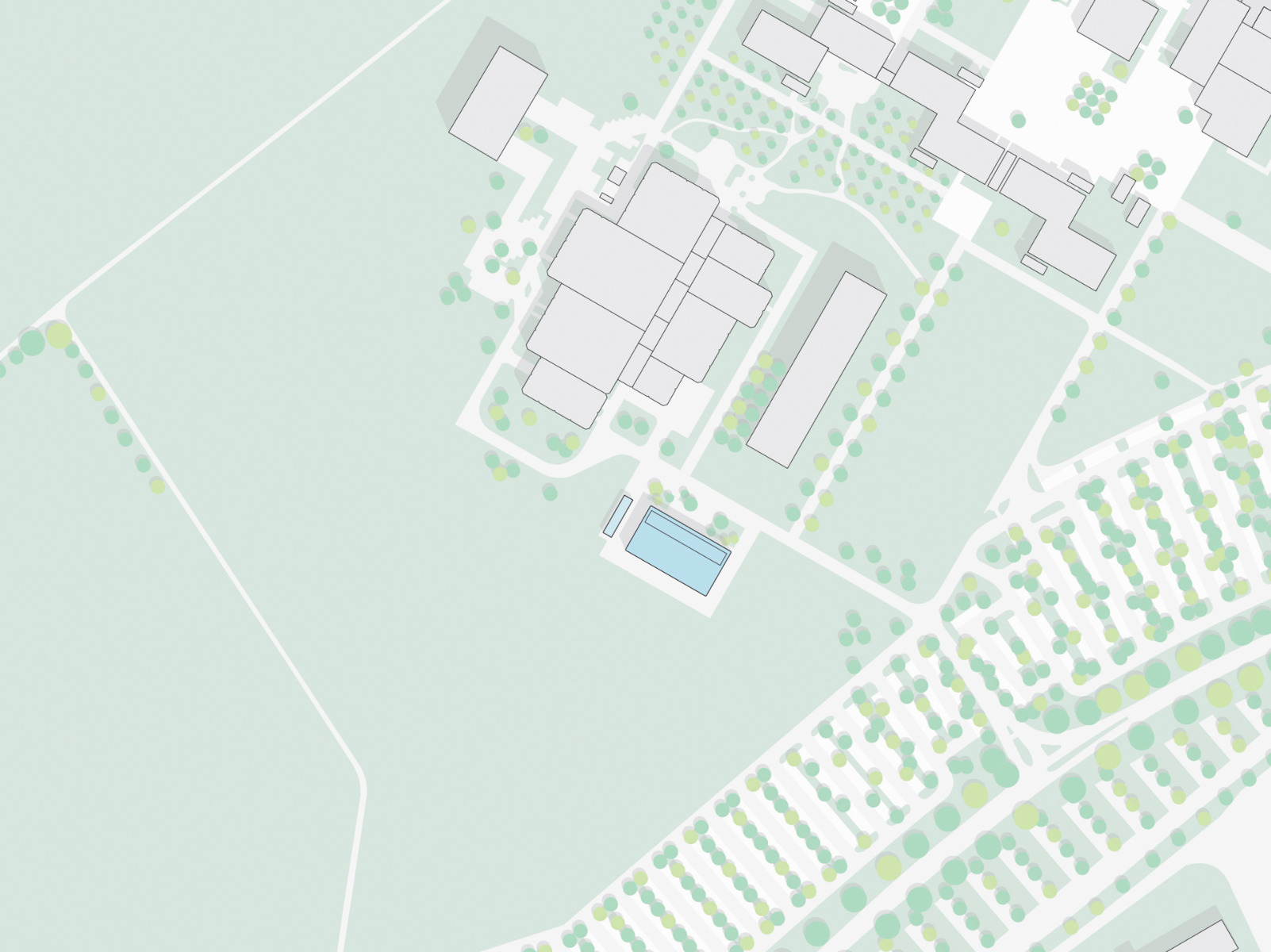

Reutlingen University has moved into Texoversum, the new building devoted to textile research. The robotically produced shell of fibrous composite materials represents a collaborative project by Allmannwappner Architekten, Menges Scheffler Architekten and the structural engineers from Jan Knippers Ingenieure.

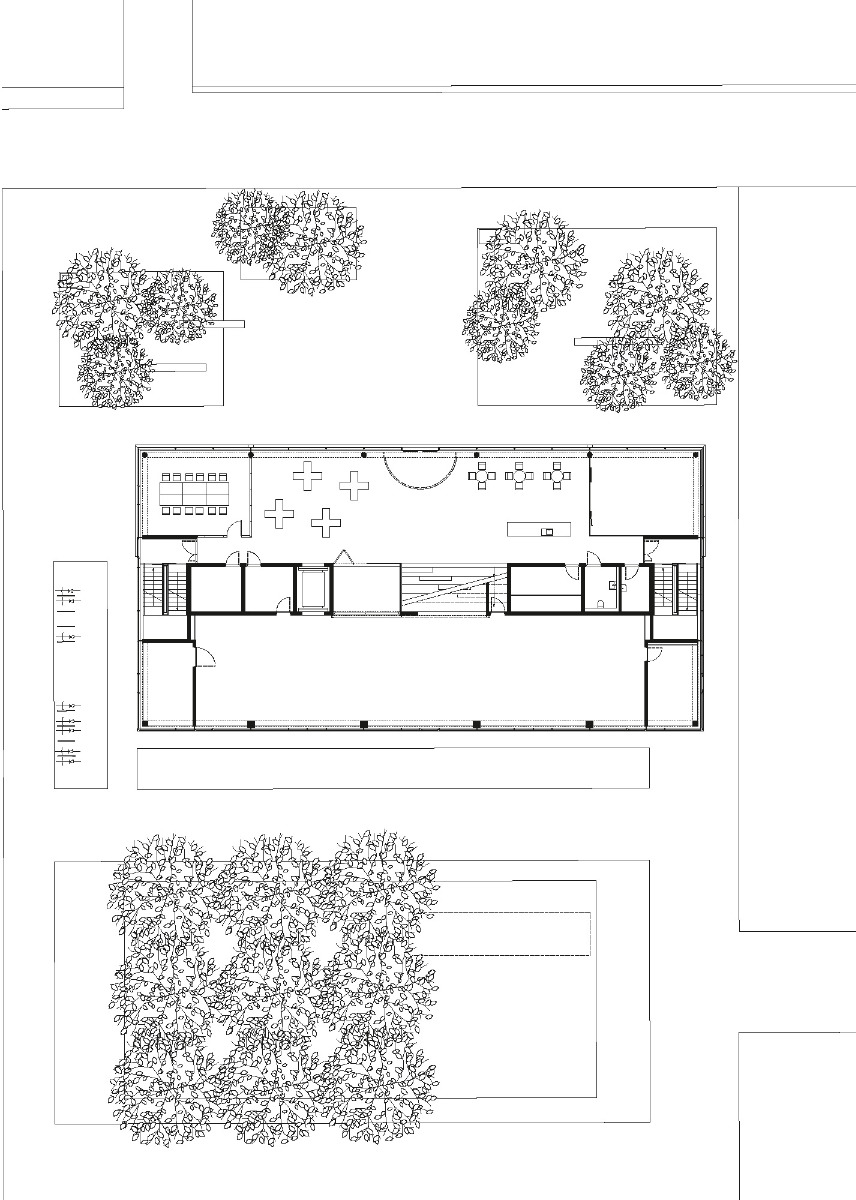

The new spaces cover 3000 m² of floor space. © Brigida González

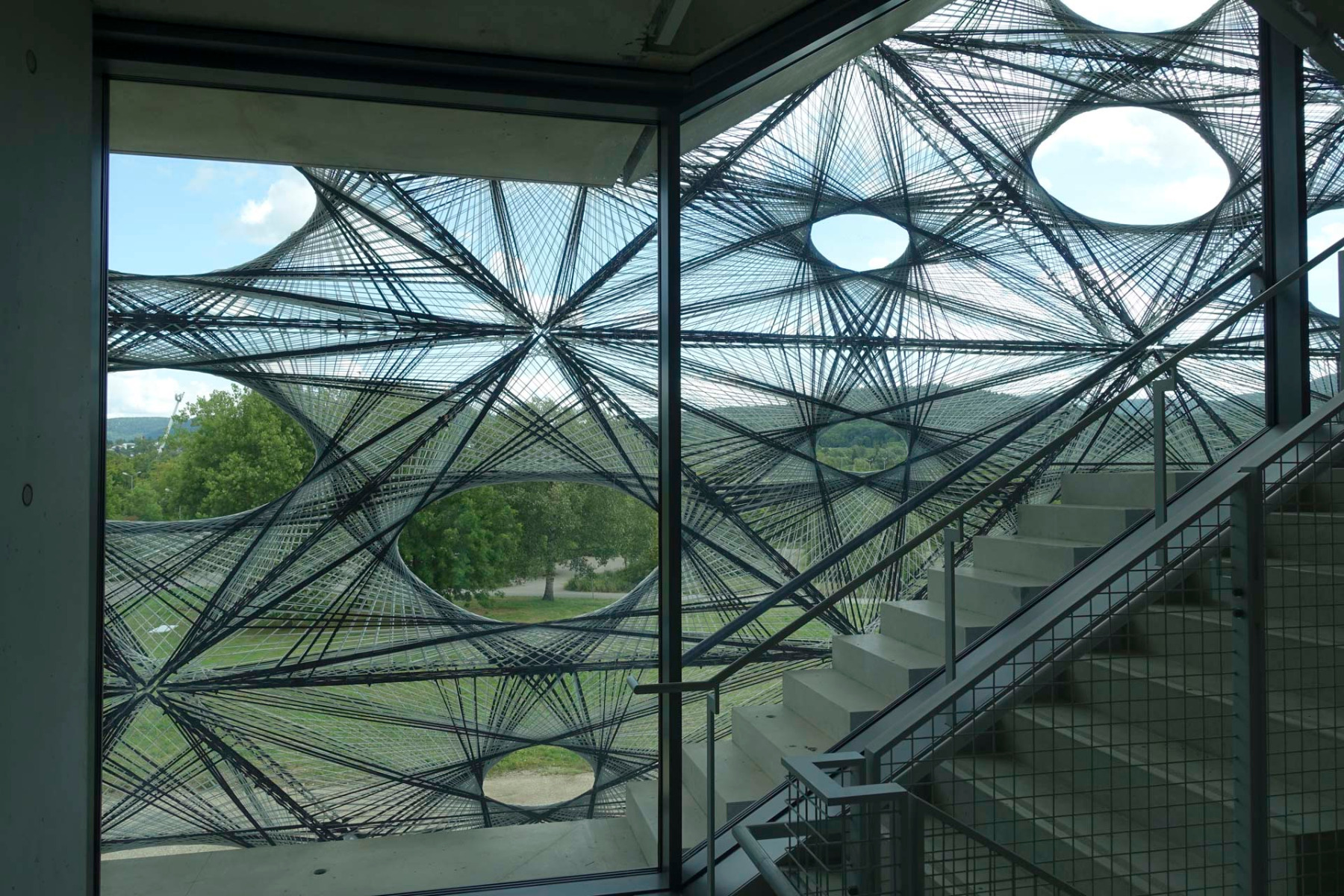

The new spaces extend over 3000 m² of usable area where teaching and research will create new synergy effects in close dialogue with the local textile industry. To ensure that this dialogue among the various specializations and other parties can be as interactive as possible, the individual functional areas are not separated from each other on closed-off storeys of the building. Rather, they are connected via a split-level arrangement, a central hall and a diversity of spaces for access and communication.

A facade of fibres

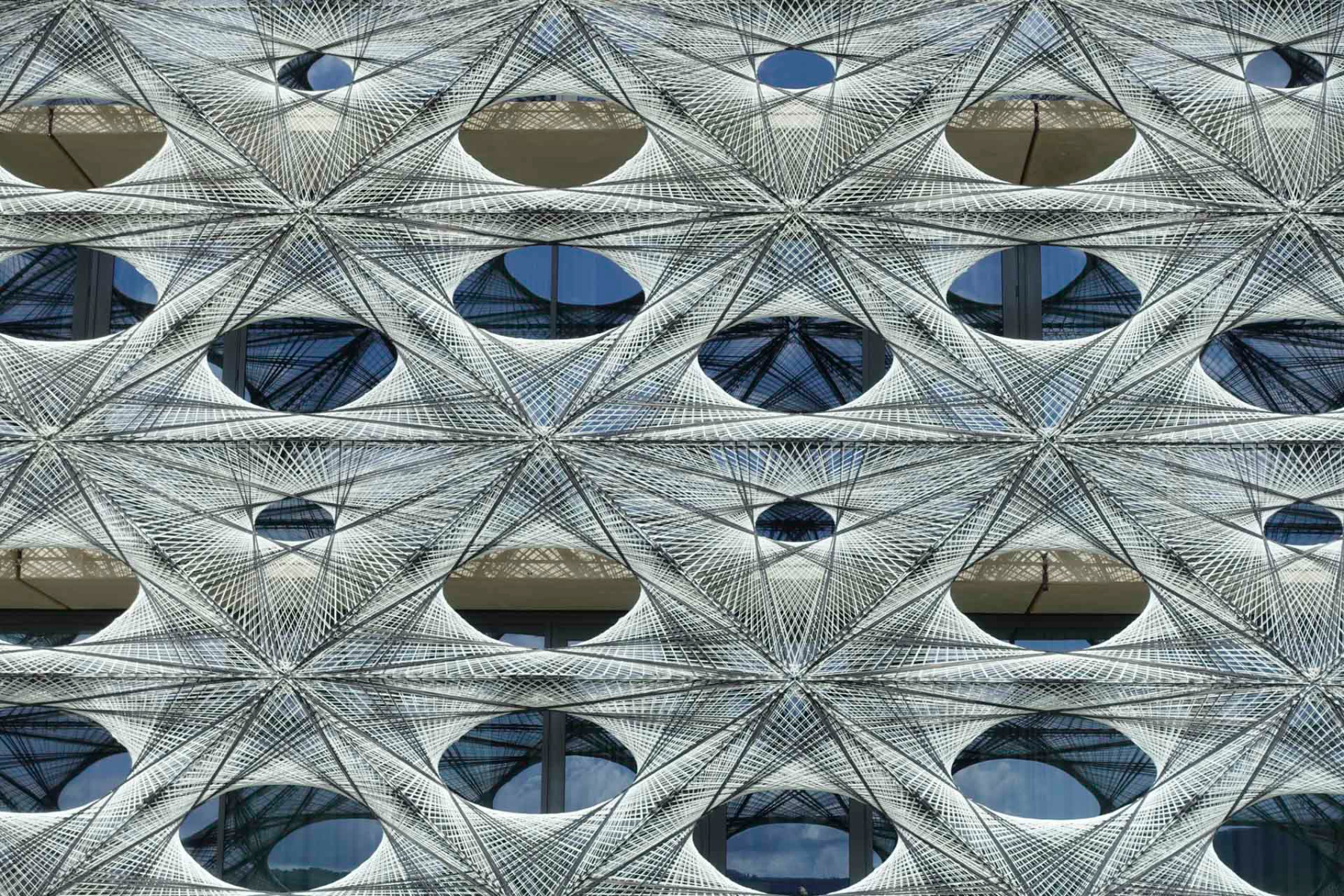

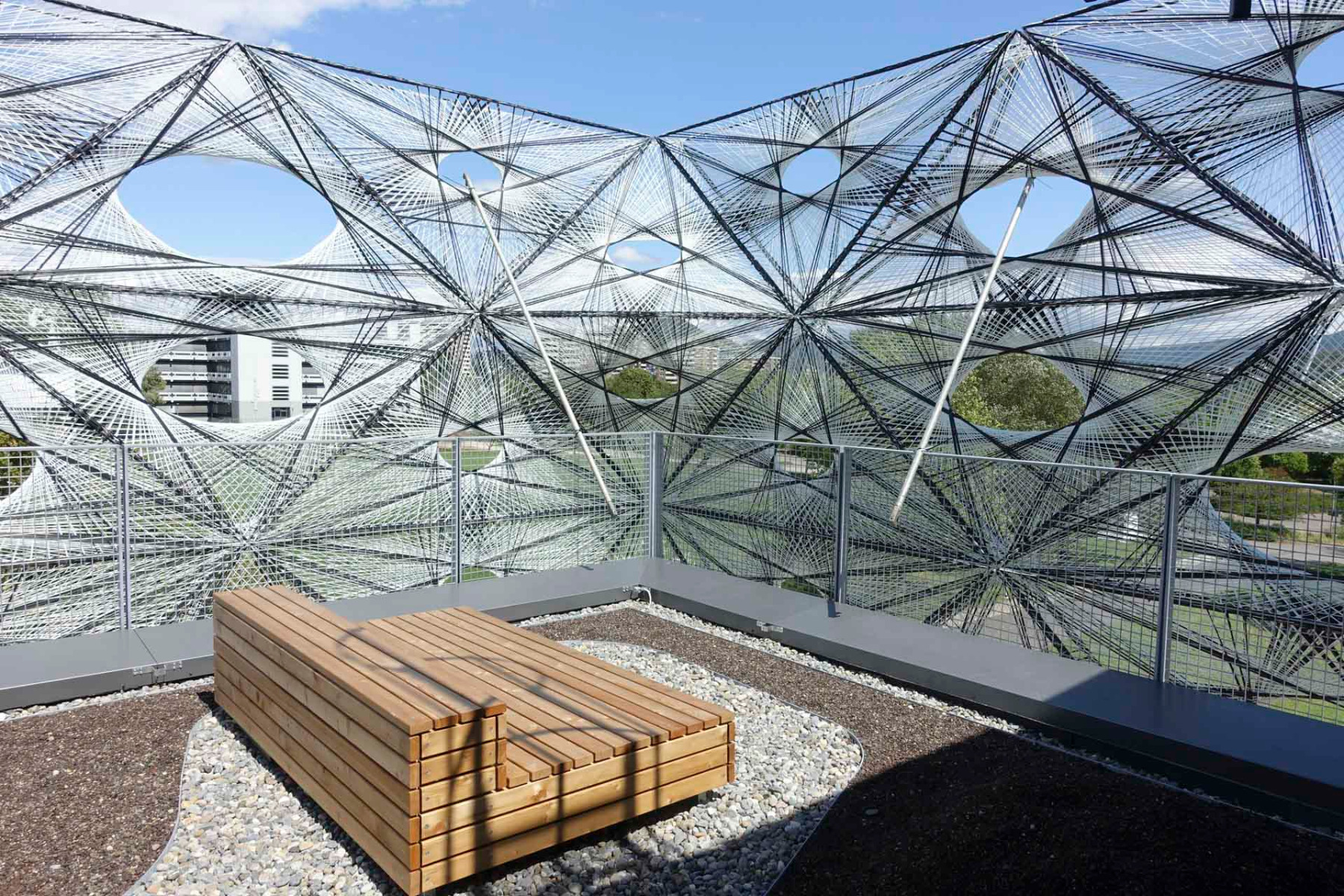

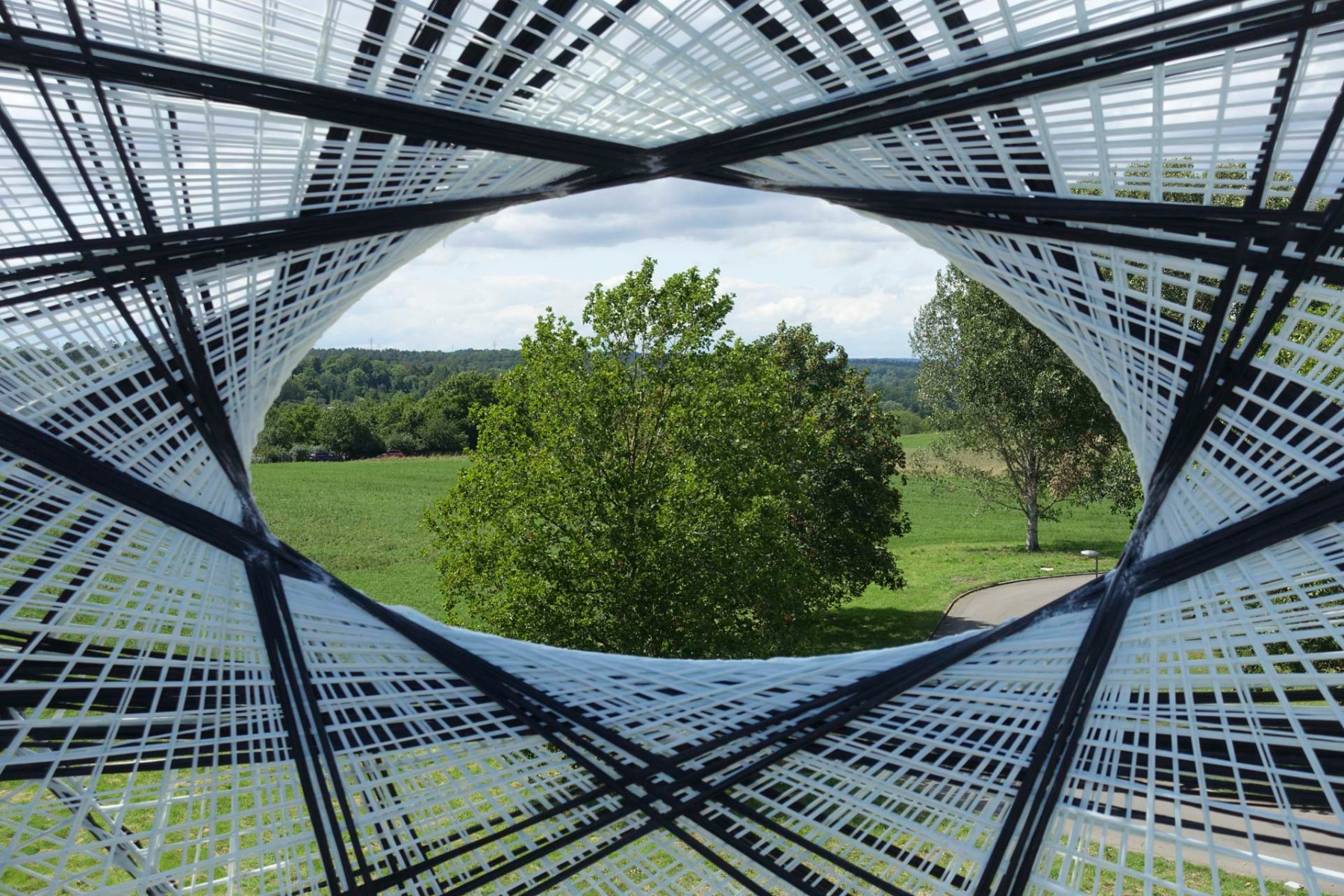

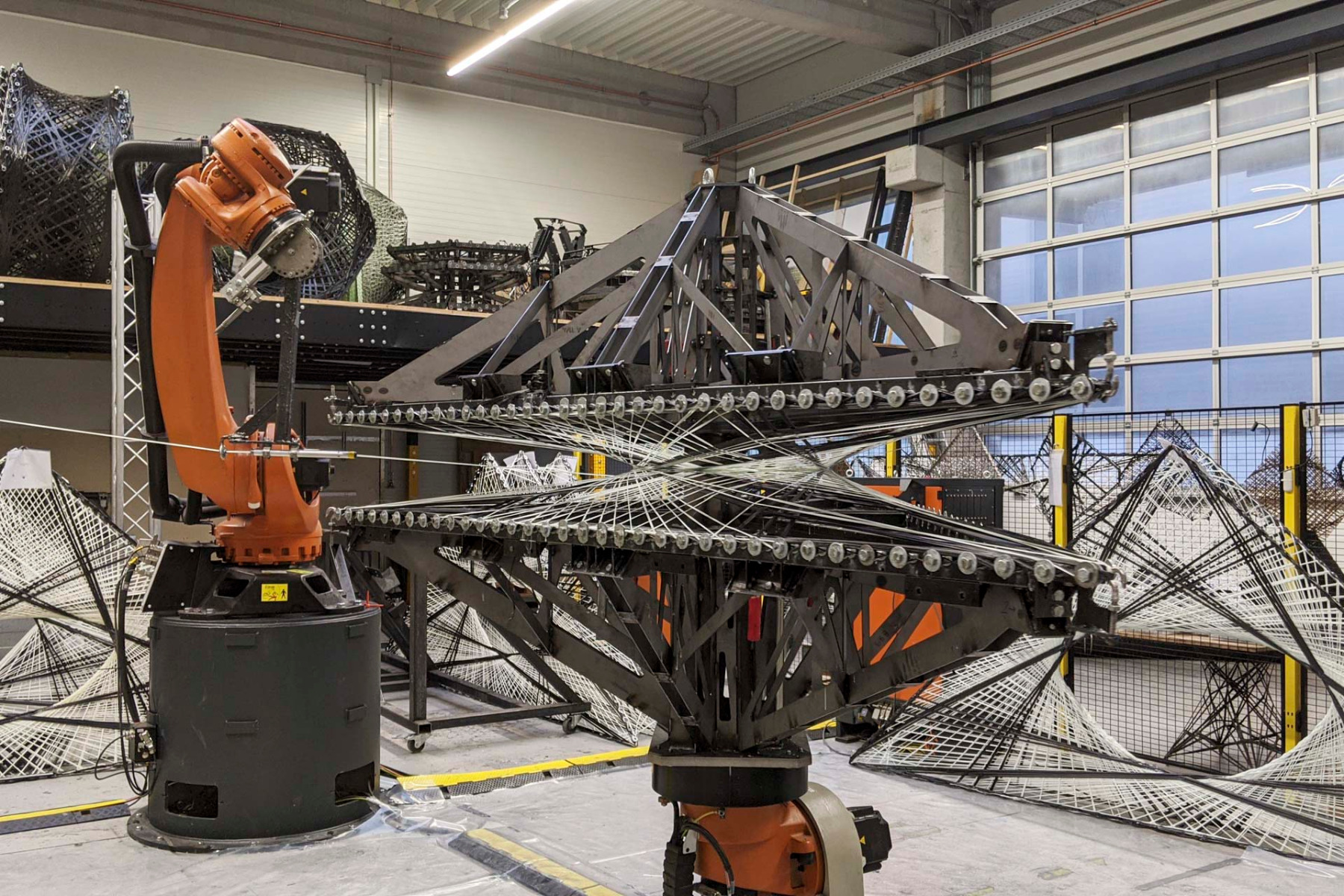

While the design of the interior spaces is restrained and functionally neutral, the specially developed 1800-m² textile shell gives the building an unmistakable, iconographic appearance: factory-prefabricated elements of carbon and glass surround the transparent cube like a woven gown. The fibres have been impregnated with resin and wound by robots in a fully automated process.

Textile fiber facade, © Frank Kaltenbach

This process was developed more than ten years ago at the Institute for Computational Design and Construction and the Institute of Building Structures and Structural Design at the University of Stuttgart. The company Fibr was born of this fundamental research; the firm has since realized many pavilions at the university as well as other structures.

Like a woven dress, the elements of carbon and glass prefabricated in the factory surround the transparent cube. © Frank Kaltenbach

Experimental technology

The Texoversum is the first successful attempt to transfer this once-experimental technology and use of materials from the academic context to a permanent building in the form of a pre-hung sunshade facade. The result is not only technologically innovative, but architecturally convincing as well: depending on the angle of the sun’s rays, the backlit glass fibres twinkle between the load-bearing carbon fibres of the webbing and transform the new building into an organic-looking eye-catcher against the rolling backdrop of the Swabian Jura mountains. As corporate architecture, the shell of Texoversum embodies the Swabian textile industry’s claim to a leading position in the global competition.

Read more in Detail 10.2023 and in our databank Detail Inspiration.

Architecture: Allmannwappner, Menges Scheffler Architekten, Jan Knippers Ingenieure

Client: Südwesttextil – Verband der Südwestdeutschen Textil- und Bekleidungsindustrie e.V.

Location: University of Reutlingen, Alteburgstraße 150, 72762 Reutlingen (DE)

General planning: Allmannwappner

Object planning: Allmannwappner

Object planning textile facade: Menges Scheffler Architekten

Structural engineering textile facade: Jan Knippers Ingenieure

Structural engineering building: bwp Burggraf+ Reiminger

Landscape planning: Glück Landschaftsarchitektur

Production and assembly textile facade: Fibr