Future Trend: Living in Garbage?

Foto: © Zooey Braun, Stuttgart

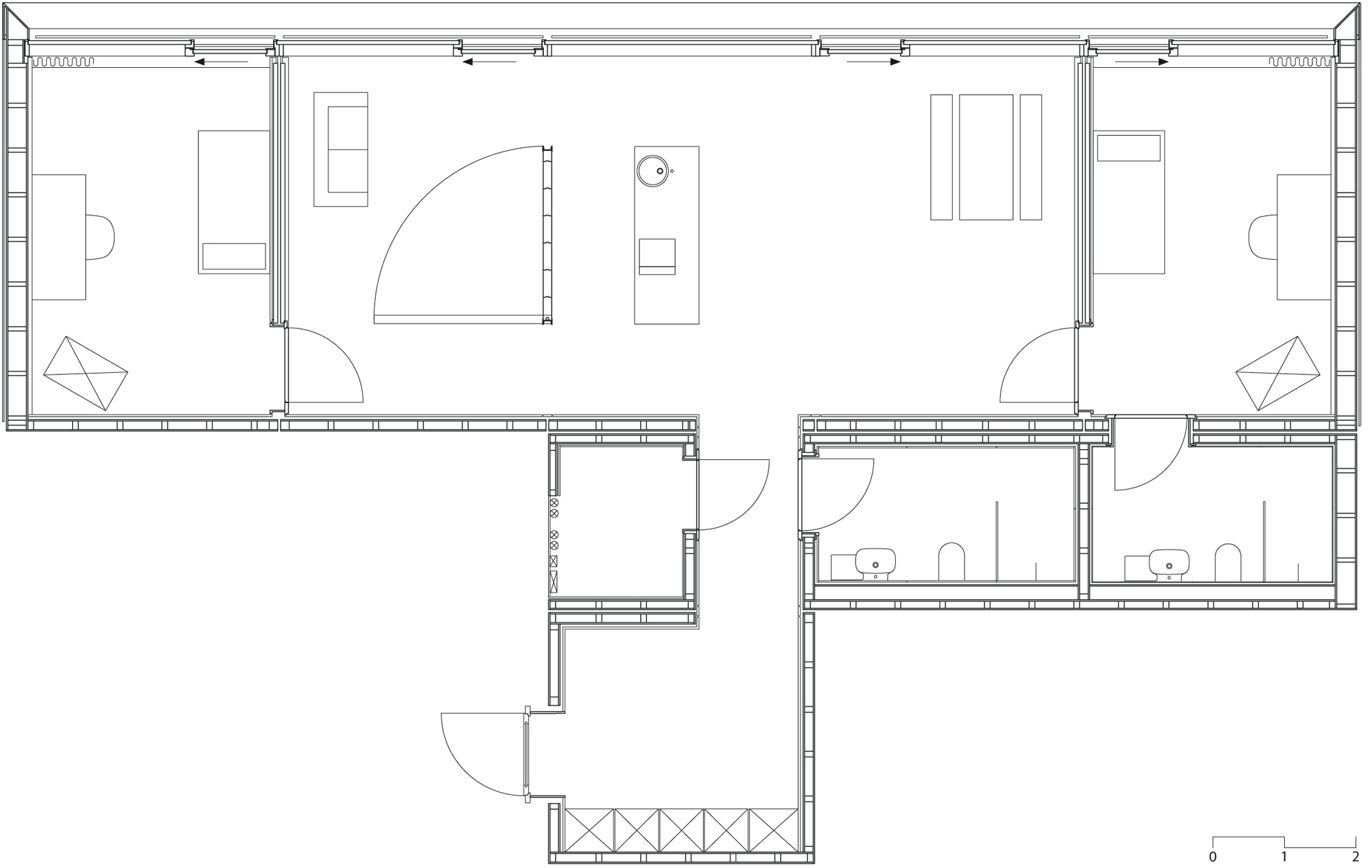

In the favelas, living in garbage has been part of everyday life for millions of slum residents. Now, reprocessing building materials as prefabricated cubicles will be used even in upper-crust neighbourhoods. First, the Urban Mining and Recycling Unit (UMAR) has to be tested in practice. Two students will shortly move into the prototype set up in the NEST research building on 8 February.

Distressing images for Western sensibilities: pictures of people who root through garbage dumps to look for usable rubbish and patch together primitive accommodations made of found plastic sheeting, pieces of corrugated metal or old tires. In Mumbai, entire branches of industry live on this type of recycling, which has entered modern urban language as “urban mining”. People are no longer mere consumers, but also producers of anthropogenic materials.

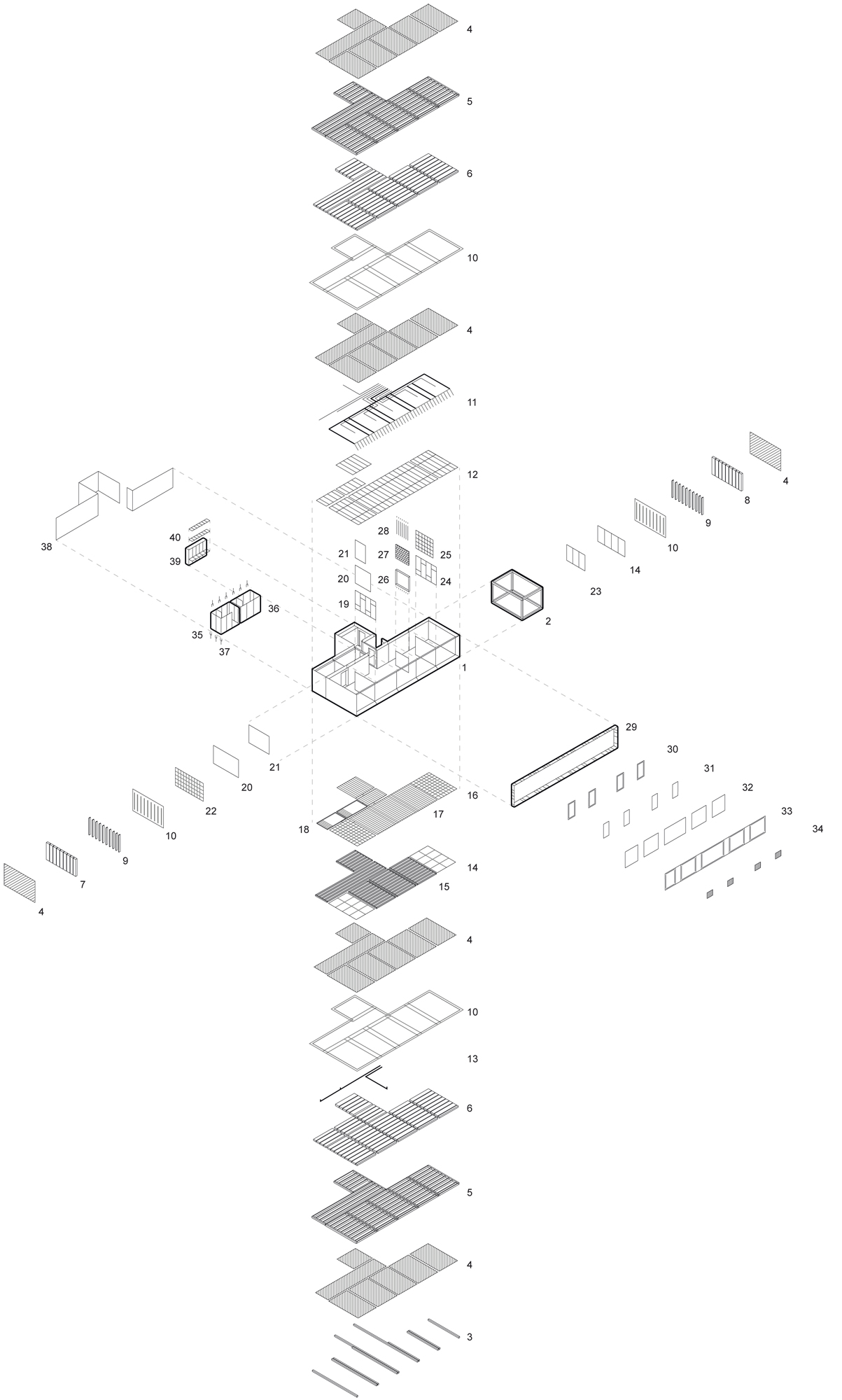

Keeping and using these materials for high-quality residential structures is the aim of the initiators of UMAR. The bronze doorknobs, which feature a patina, come from a Brussels hotel; the insulation is made of torn jeans. The black dapple surfaces could become the marble of post-fossil society. Black dapple consists of highly densified slices of polyethylene made of cutting boards and plastic wrapping.

“In the face of our rapidly growing world population, we will have to drastically reduce our use of materials for individual apartments in the future,” claims Werner Sobek, who developed UMAR along with Dirk E. Hebel and Felix Heisel. There is more: once an apartment has reached the end of its lifespan, the components of UMAR will flow back into material circulation. This means that all the joints are easy to take apart, in keeping with the principle of pinning instead of gluing.

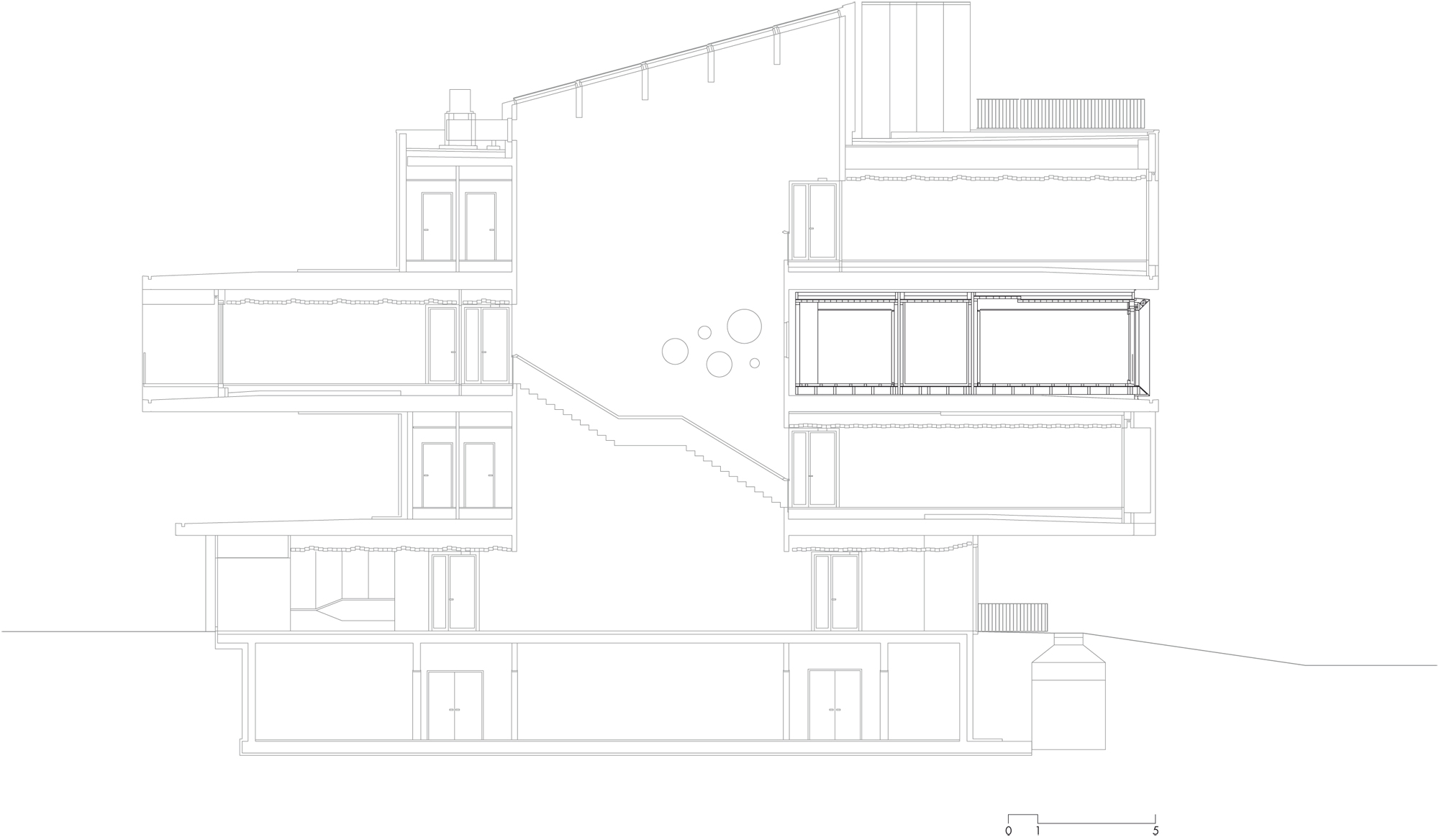

UMAR is just one of 10 units that will be set up in the modular NEST research and innovation building belonging to Empa and Eawag in Dübendorf, an area in the north of Zurich. The other units at NEST (Next Evolution in Sustainable Building Technologies) work with adjustable panels of high-efficiency membranes of photovoltaic cells, innovative concrete shells, new types of wood materials or assistance systems which enable the elderly to remain in their homes as long as possible despite increasing frailty. The fact that test subjects live and work in the units make this a living lab, or a combination of living/office and laboratory space.

A further remarkable characteristic of UMAR is the international work of the materials testing organization known as Empa in collaboration with the Werner Sobek Group, the University of Stuttgart (Werner Sobek) and the Karlsruhe Institute of Technology (Dirk E. Hebel and Felix Heisel). In fact, the research project now extends far beyond Switzerland’s borders.

Anyone who would like to form an impression of the project can take part in a one-hour tour on location. Further information.

Distressing images for Western sensibilities: pictures of people who root through garbage dumps to look for usable rubbish and patch together primitive accommodations made of found plastic sheeting, pieces of corrugated metal or old tires. In Mumbai, entire branches of industry live on this type of recycling, which has entered modern urban language as “urban mining”. People are no longer mere consumers, but also producers of anthropogenic materials.

Keeping and using these materials for high-quality residential structures is the aim of the initiators of UMAR. The bronze doorknobs, which feature a patina, come from a Brussels hotel; the insulation is made of torn jeans. The black dapple surfaces could become the marble of post-fossil society. Black dapple consists of highly densified slices of polyethylene made of cutting boards and plastic wrapping.

“In the face of our rapidly growing world population, we will have to drastically reduce our use of materials for individual apartments in the future,” claims Werner Sobek, who developed UMAR along with Dirk E. Hebel and Felix Heisel. There is more: once an apartment has reached the end of its lifespan, the components of UMAR will flow back into material circulation. This means that all the joints are easy to take apart, in keeping with the principle of pinning instead of gluing.

UMAR is just one of 10 units that will be set up in the modular NEST research and innovation building belonging to Empa and Eawag in Dübendorf, an area in the north of Zurich. The other units at NEST (Next Evolution in Sustainable Building Technologies) work with adjustable panels of high-efficiency membranes of photovoltaic cells, innovative concrete shells, new types of wood materials or assistance systems which enable the elderly to remain in their homes as long as possible despite increasing frailty. The fact that test subjects live and work in the units make this a living lab, or a combination of living/office and laboratory space.

A further remarkable characteristic of UMAR is the international work of the materials testing organization known as Empa in collaboration with the Werner Sobek Group, the University of Stuttgart (Werner Sobek) and the Karlsruhe Institute of Technology (Dirk E. Hebel and Felix Heisel). In fact, the research project now extends far beyond Switzerland’s borders.

Anyone who would like to form an impression of the project can take part in a one-hour tour on location. Further information.

Urban Mining & Recycling project team

Builder: Empa, Swiss Federal Laboratories for Materials Testing and Research, Dübendorf, Switzerland

Concept, design, and project planning: Werner Sobek with Dirk E. Hebel and Felix Heisel, Stuttgart and Karlsruhe, Germany

Structural design and general contractor: Kaufmann Zimmerei und Tischlerei GmbH, Reuthe, Austria

HVAC, sanitation, and electrical systems, and measurement and control: Amstein-Walthert AG, Zürich, Switzerland

Sprinklers: NBG Ingenieure AG, Bern, Switzerland; JOMOS Feuerschutz AG, Balsthal, Switzerland

Fire protection: Balzer Ingenieure AG, Chur, Switzerland

Building physics: Weber Energie und Bauphysik, Schaffhausen, Switzerland

Builder: Empa, Swiss Federal Laboratories for Materials Testing and Research, Dübendorf, Switzerland

Concept, design, and project planning: Werner Sobek with Dirk E. Hebel and Felix Heisel, Stuttgart and Karlsruhe, Germany

Structural design and general contractor: Kaufmann Zimmerei und Tischlerei GmbH, Reuthe, Austria

HVAC, sanitation, and electrical systems, and measurement and control: Amstein-Walthert AG, Zürich, Switzerland

Sprinklers: NBG Ingenieure AG, Bern, Switzerland; JOMOS Feuerschutz AG, Balsthal, Switzerland

Fire protection: Balzer Ingenieure AG, Chur, Switzerland

Building physics: Weber Energie und Bauphysik, Schaffhausen, Switzerland