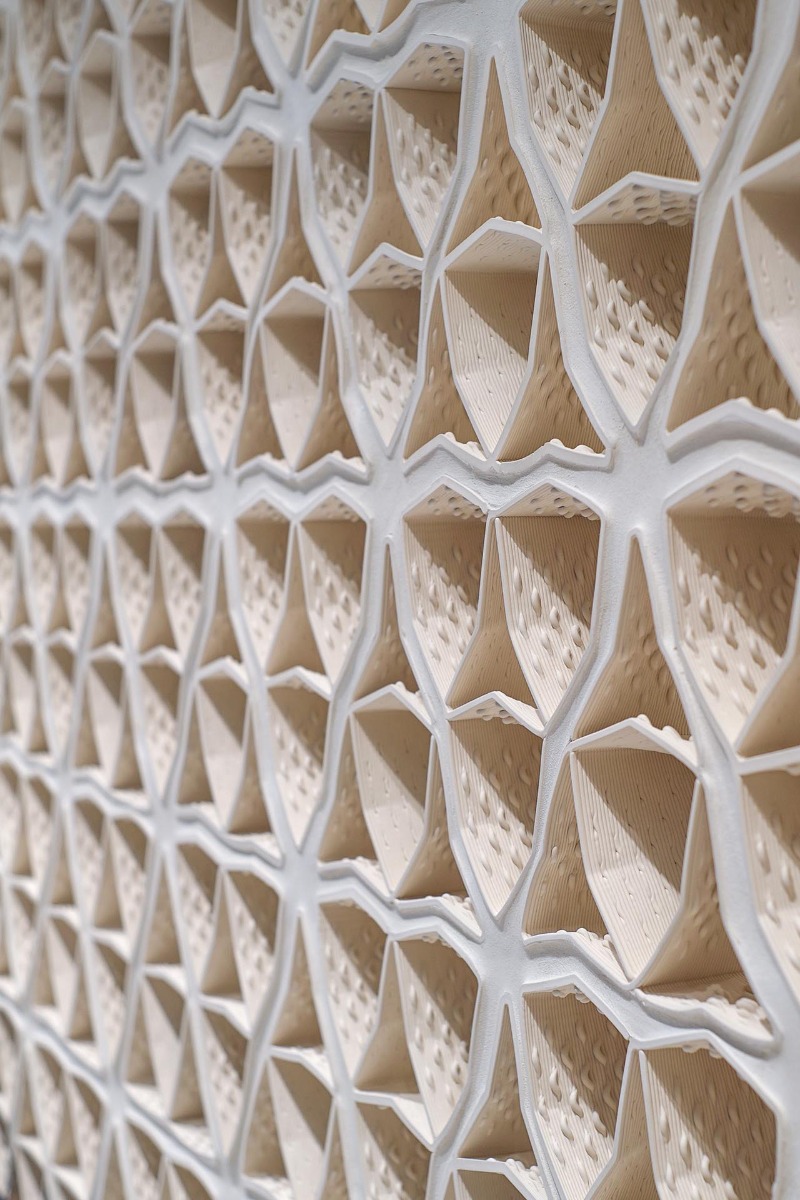

A 3D-printed clay wall

Hive Research Project at the University of Waterloo

© Shabaan Khokhar

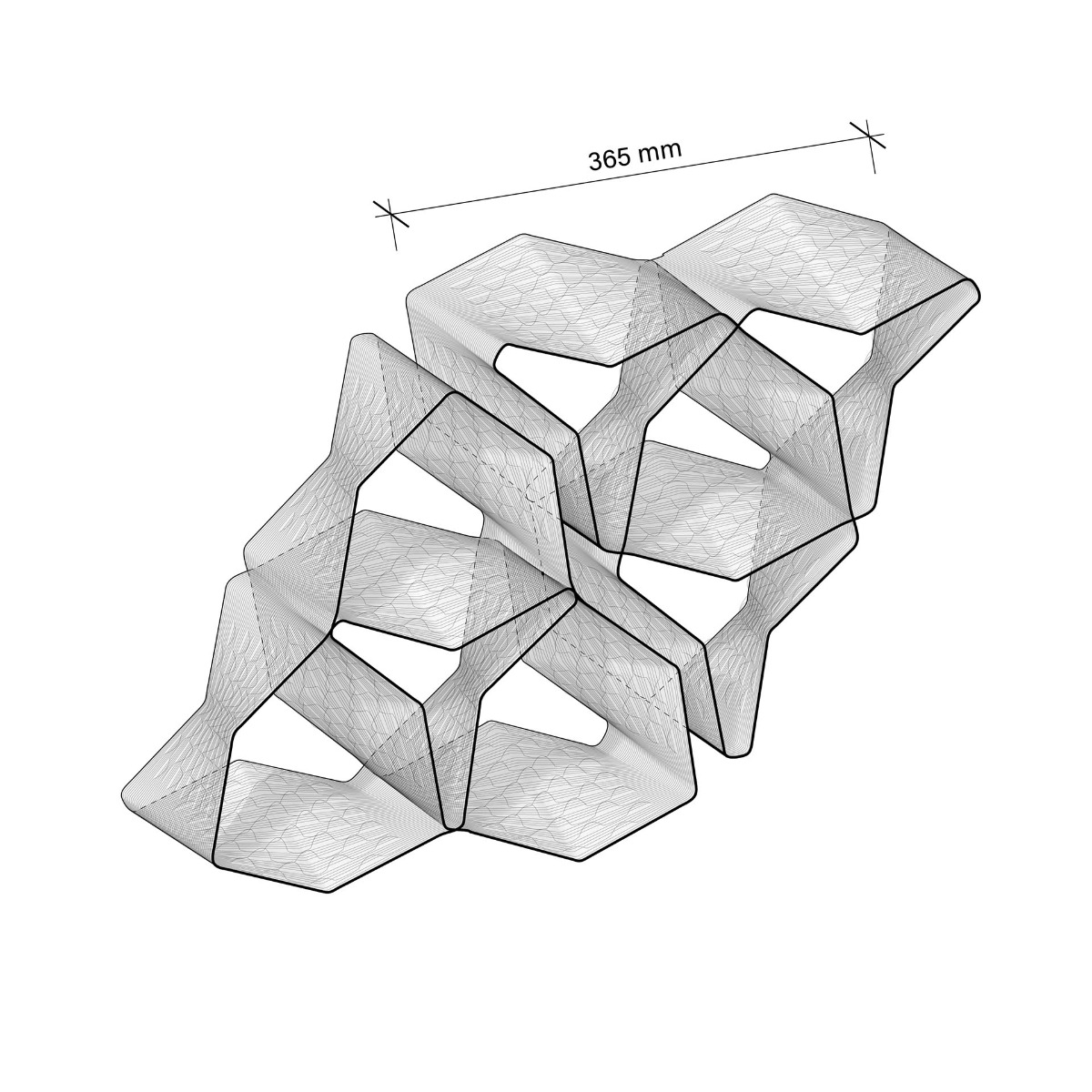

Traditional material and robot-supported production meld to create digital artisanship. Students at the University of Waterloo have developed a flexible wall of 3D-printed clay bricks for interior spaces.

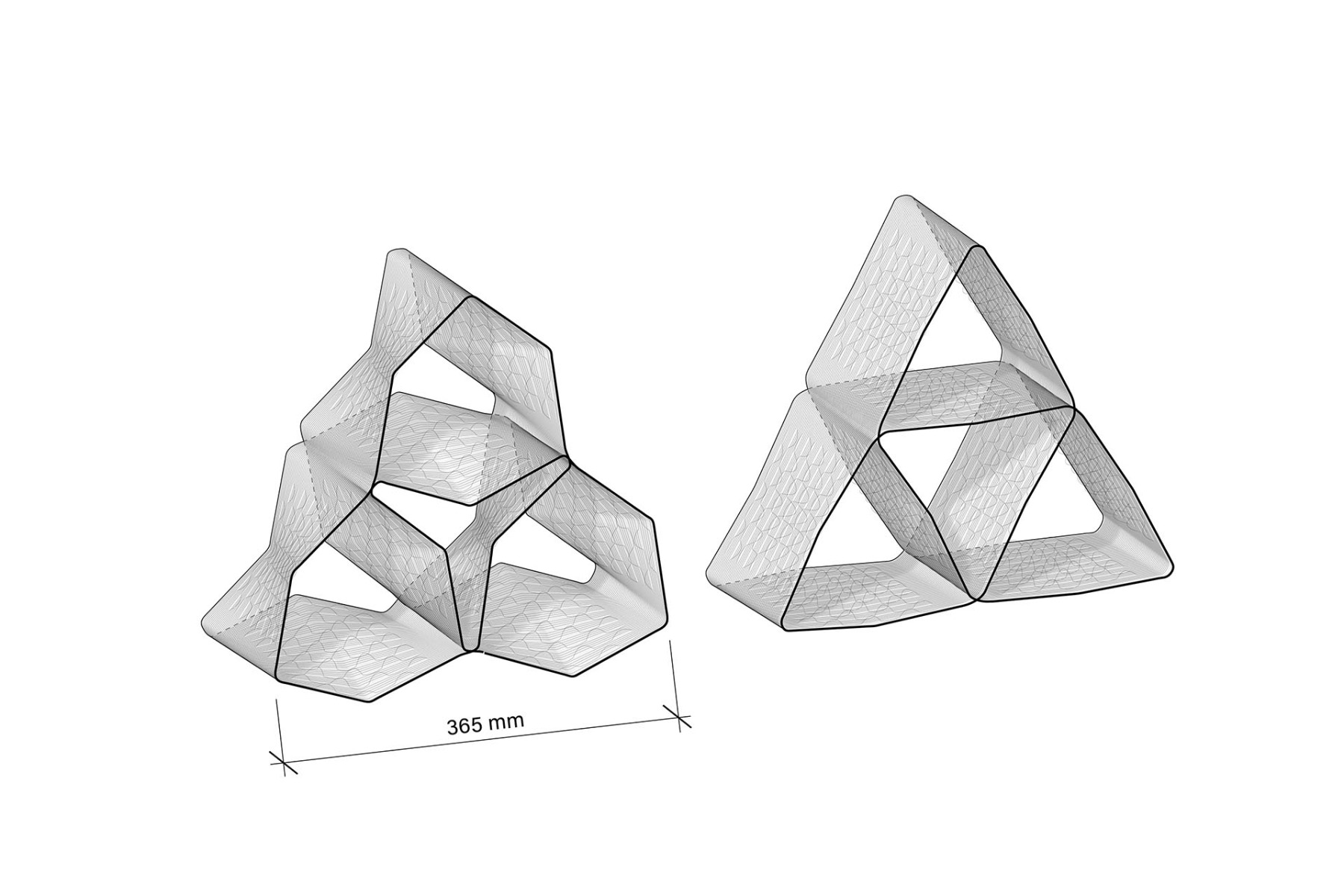

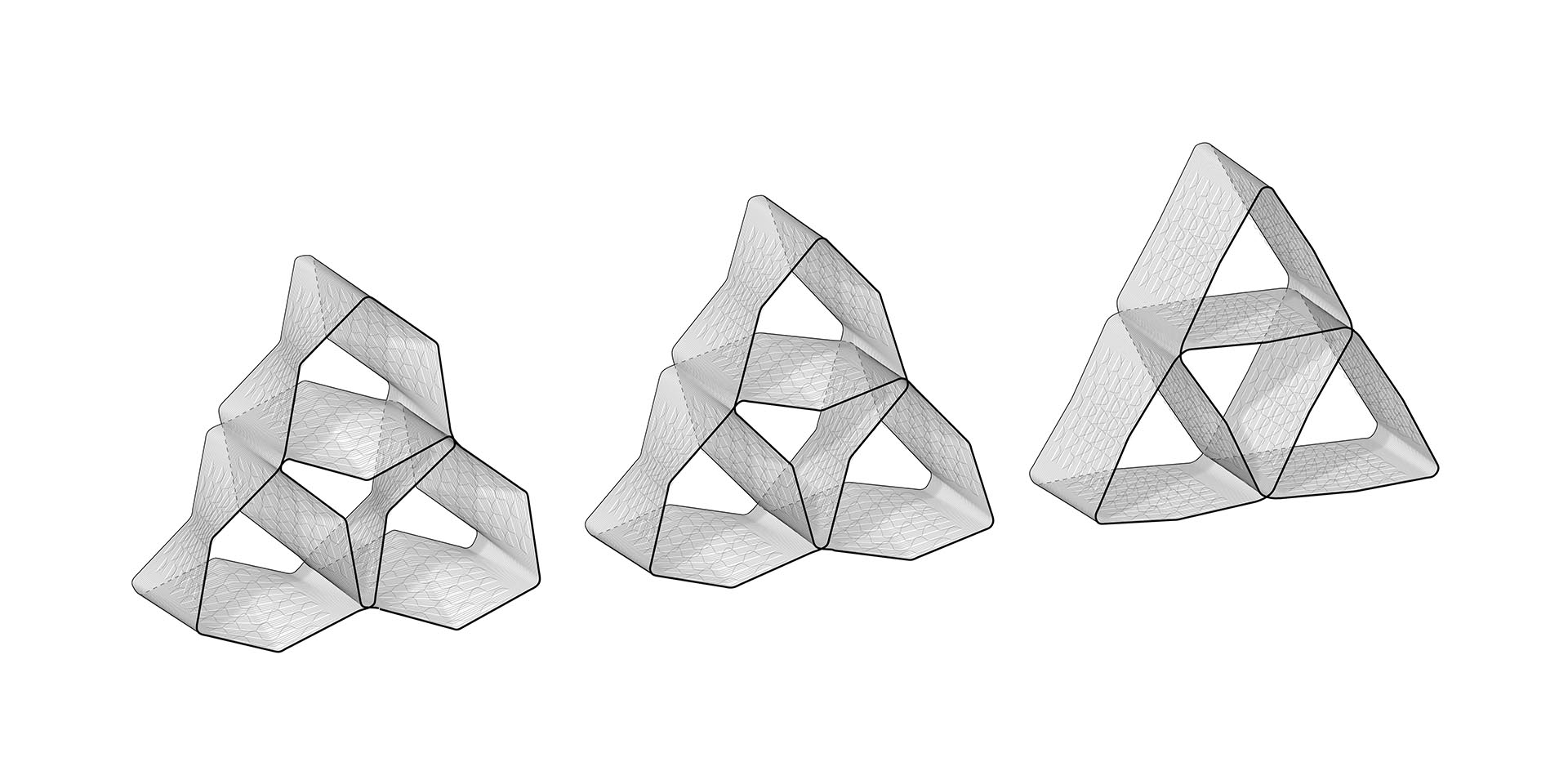

The Hive project encompasses 175 printed clay bricks. © Fred Hunsberger

A lightweight clay wall

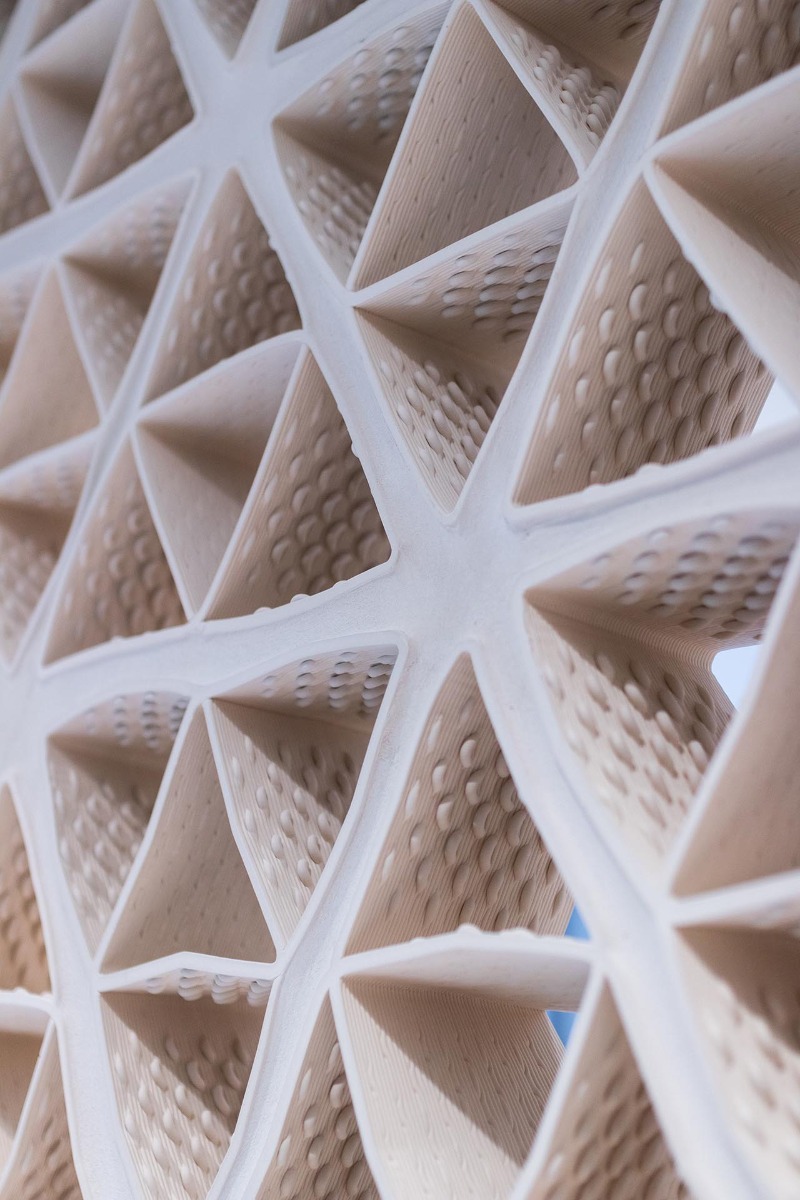

The Hive project encompasses 175 printed clay bricks that form a flexible wall that can be used to design interior spaces. The hexagonal bricks were created in an iterative design and production process that sees new applications for the traditional material clay.

The students explored the material mixture, which is suitable for 3D printing, conceived digital tools for design and production, and carried out a great number of material tests before setting up their wall.

The students explored the material mixture. © Fred Hunsberger

Digital artisanship

Hybrid work is increasingly winning recognition. This Canadian interior project demonstrates the degree to which traditional materials and digital design have meshed in recent years. Robot-supported precision is developing with materials such as clay as well. Digital artisanship connects thousands of years of knowledge with robot-supported precision and new possibilities for design.

Hive is a flexible wall of 3D-printed clay bricks for interior spaces.. © Shabaan Khokhar

The hexagonal bricks were created in an iterative design and production process. © Shabaan Khokhar

Research partnership

An important question surrounded the cost-effectiveness of digital work with clay, as well as the potential offered by 3D printing in designing complex geometries. Hive is the result of a research partnership between the University of Waterloo and the Investment Management Corporation of Ontario (IMCO). The project was commissioned by SDI Interior Design and supported by the Masonry Works Council of Ontario.

Design & Development: Ye Sul E. Cho (Project Lead, Alumna, Waterloo Architecture), Ji Shi (Sci. Development Lead, Alumnus, Waterloo Architecture), Meghan Taylor (Alumna, Waterloo Architecture), David Correa (PI, Assistant Professor, Waterloo Architecture), James Clarke-Hicks (Graduate Researcher, Waterloo Architecture), Isabel Ochoa (Graduate Researcher, Waterloo Architecture)

Technical Support: Heinz Koller (Shop Manager, Waterloo Architecture), Mychael Syms (Shop Technician, Waterloo Architecture), B. Mingyuan Ma, (Student, Waterloo Architecture)

Interior Design: SDI Design, Joanne Chan, Bruce Freeman

Project Management: Cresa Toronto, Michael Wasyliw

Industry Partners: Masonry Works Council of Ontario, Andrew Payne, Quikrete/Spec Mix., Dean Garbutt

Installation: Page Flooring & Concrete Solutions, Tony Natali

Project Commission: Investment Management Corporation of Ontario