Research

Building Components Made of Natural Fibres

© LZH

Transdisciplinary collaboration

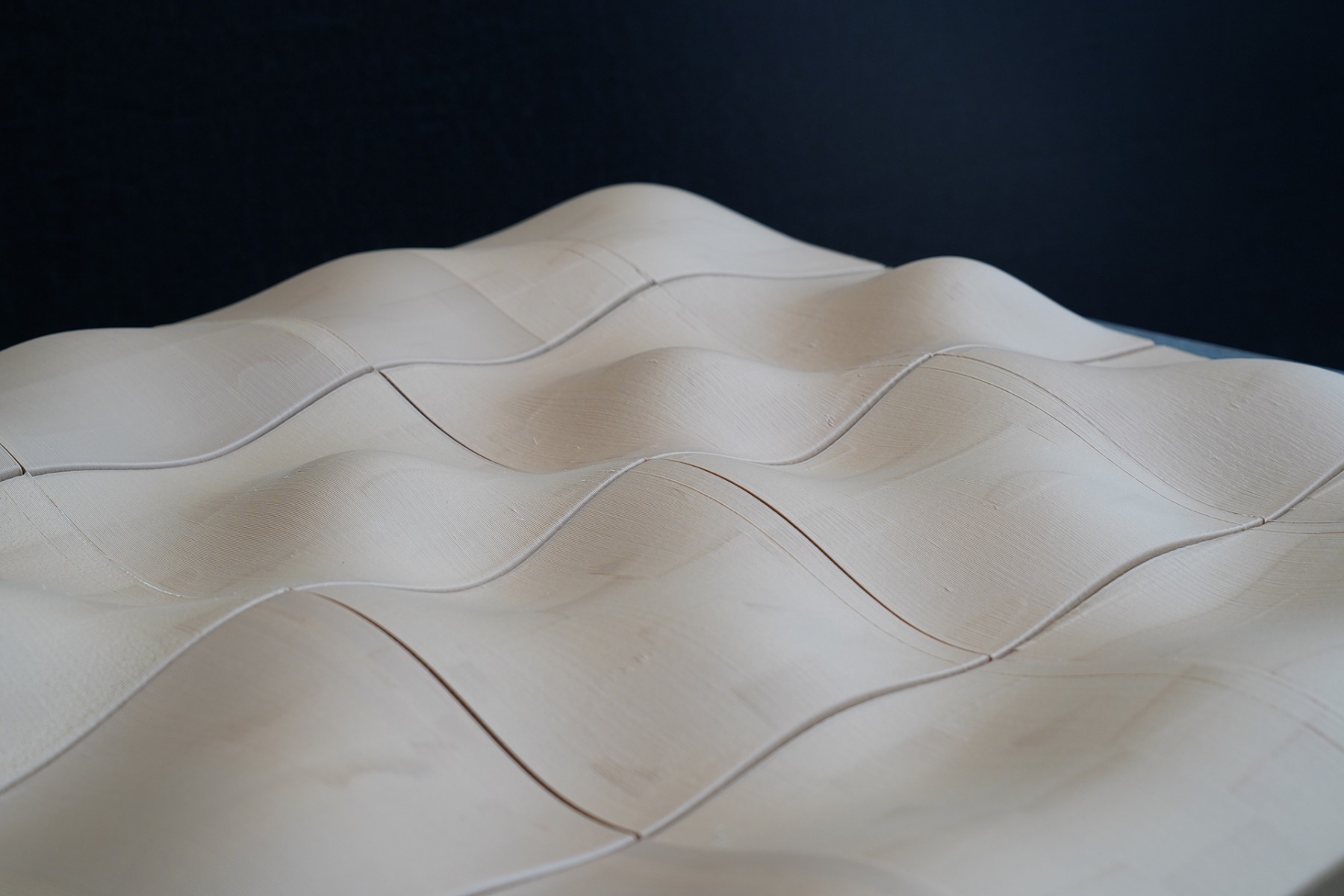

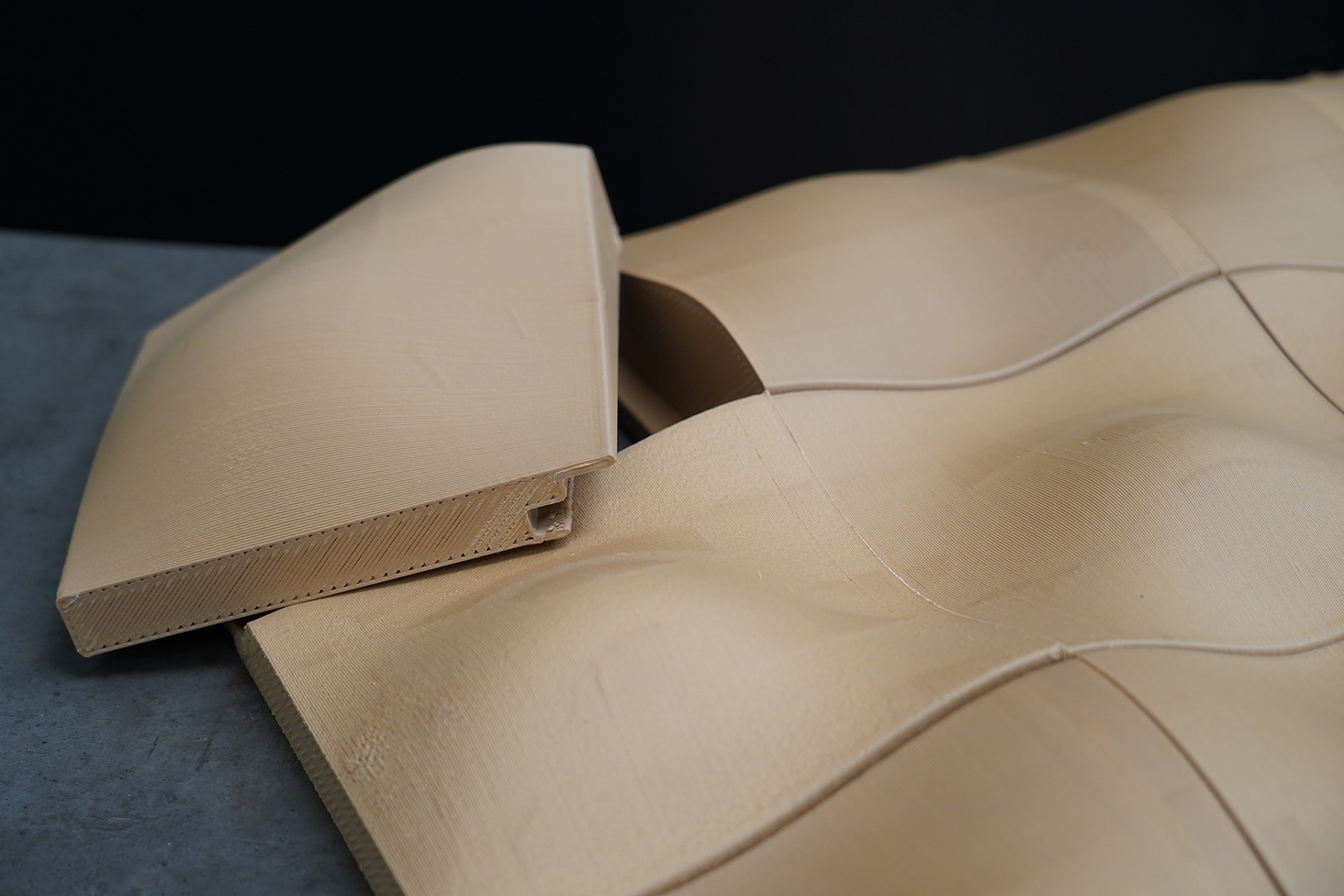

Along with the Laser Zentrum Hannover (LZH) and other partners, the Department BioMat (Bio-based Materials and Material Cycles in Architecture) at the Institute of Building Structures and Structural Design (ITKE) Stuttgart is investigating how innovative building elements made of natural fibres can grow with additive production methods. This research will focus on 3D-printed facade elements consisting of biopolymers reinforced with natural fibres.

© LZH

The biopolymer advantage

In the 3DNaturDruck project, researchers from various disciplines first optimize composites made of biopolymers (natural short fibres such as wood and straw or natural continuous fibres such as hemp and flax) to be used in FDM (Fused Deposition Modelling). The resulting architectural building components will be on a par with conventional elements (polymers based on fossil resources).

© LZH

Creative scope

The aim of the project is the construction of a complete pavilion featuring 3D-printed facade elements on the campus of the University of Stuttgart. In order to benefit from the full creative scope here, the LZH is testing all new materials and optimizing the nozzle geometry of the FDM printer. The charm of the project lies not least in the development of sustainable building materials that can ideally be recycled.

KONTAKTFORMULAR / DATEN - NUR ADVERTORIAL - Wird noch hinzugefügt @ Daniel

Architecture: BioMat (Biobased Materials and Material Cycles in Architecture) at at the Institute of Structural Engineering and Design (ITKE), University of Stuttgart

Projectteam: The project is coordinated by Prof. Hanaa Dahy from the Department BioMat (Biobased Materials and Material Cycles in Architecture) at the Institute of Structural Engineering and Design (ITKE) at the University of Stuttgart (DE) and the BioMat@Copenhagen department at Aalborg University (DK).

Projectpartner: Laser Zentrum Hannover (LZH), das Fraunhofer-Institut für Holzforschung Wilhelm-Klauditz-Institut (WKI), die Industrieunternehmen Rapid Prototyping Technologie GmbH (Gifhorn), ETS Extrusionstechnik (Mücheln), 3dk.berlin (Berlin) und ATMAT Sp. Z o.o. (Krakau, Poland)