Research

Additively Produced Aluminum Nodes from the 3D Printer

© Hochschule für Technik, Wirtschaft und Kultur Leipzig

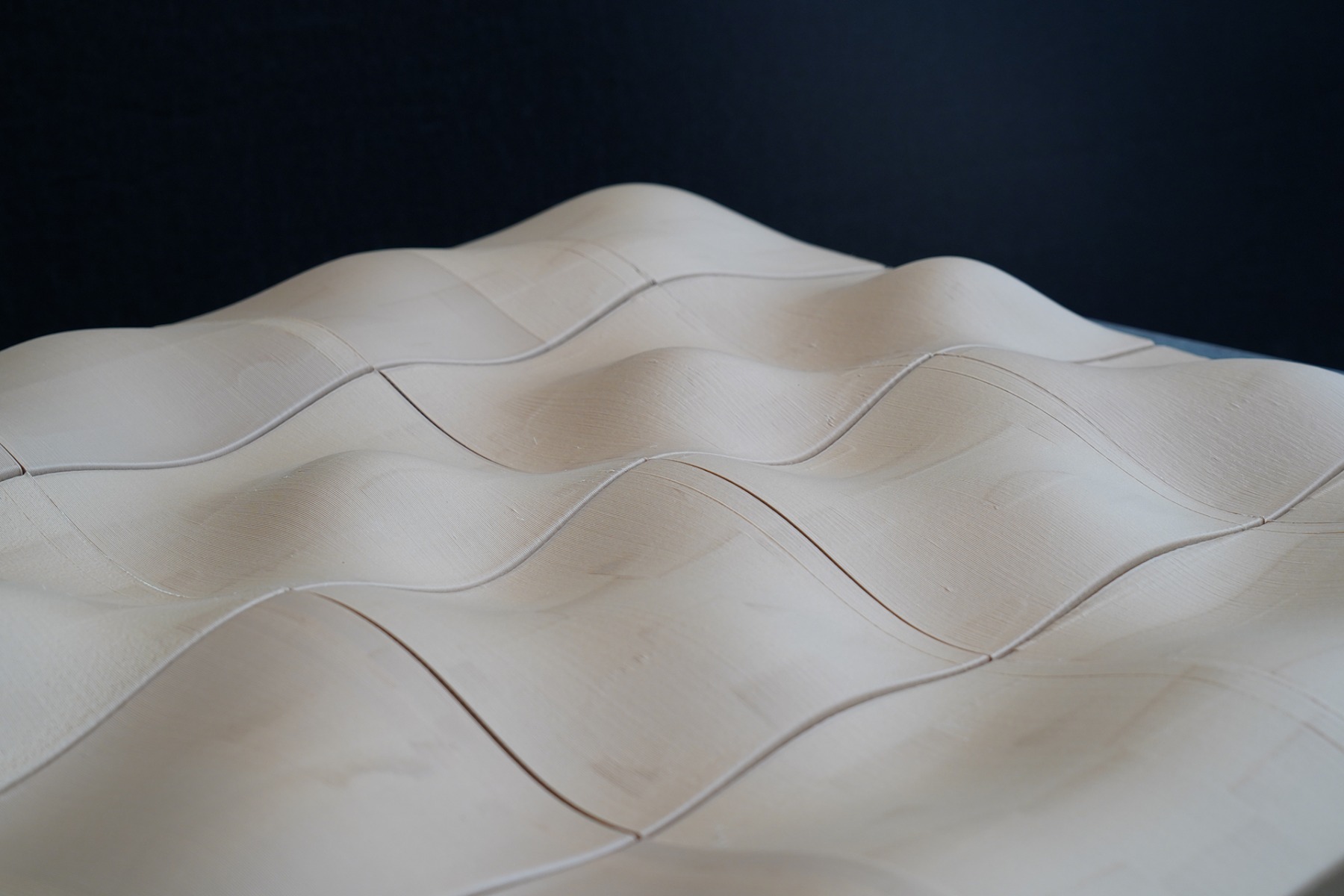

Digital concepts for design, planning and manufacturing are revolutionizing construction. One key is the timely planning of serial and additive production, which saves both materials and money. For instance, individually produced nodes enable traditional series even for geometrically complex surfaces.

© Hochschule für Technik, Wirtschaft und Kultur Leipzig

Better bionics

Learning from nature is hardly a new approach. At HTWK Leipzig, the Flex research group surrounding Alexander Stahr is working on making network structures and webs practicable for technical applications. Their work combines digital planning, additive production processes and hybrid building techniques.

Hopefully hybrid

The hybrid construction concept ParaKnot3D, which is based on an idea developed by Martin Dembski, combines traditional series production for geometrically simple surface structures with geometrically complex node elements. These are digitally designed, planned and implemented.

© Hochschule für Technik, Wirtschaft und Kultur Leipzig

The elegant InNoFa Demonstrator conserves resources, for its automated production is a prerequisite for the construction right from the start. For the Flex group, this type of continuous digital planning is “the key to significantly more material-efficient architecture”.

© Hochschule für Technik, Wirtschaft und Kultur Leipzig

Clever nodes

The researchers from Flex have designed twelve node elements of aluminum for a polymorphous facade. These were produced additively using the SLM (selective laser melting) process at the Laser Institute of the Mittweida University of Applied Sciences (LHM). The connections use algorithmic form generation to make curvature-constant transitions between rectangular hollow profiles. The mock-up is currently on public display at HTWK Leipzig.

Architecture: Hochschule für Technik, Wirtschaft und Kultur Leipzig (HTWK Leipzig), Prof. Alexander Stahr; Max Höhne, M. A.; Martin Dembski, M. Sc.; Fabian Eidner, B. A.; Theodor Reinhardt, B. A.

Partner: Laserinstitut Hochschule Mittweida, Prof. André Streek; Michael Pfeifer, M. Sc.; Martin Erler, M. Sc.

Transferverbund: Saxony5